BioXplorer 400P

Product Category: Bioprocess Development

Industry: Catalysis Chemical Synthesis and Crystallisation, Life Sciences, Pharmaceutical, Personal Care and Natural Products

Supplier: H.E.L. Group

Description

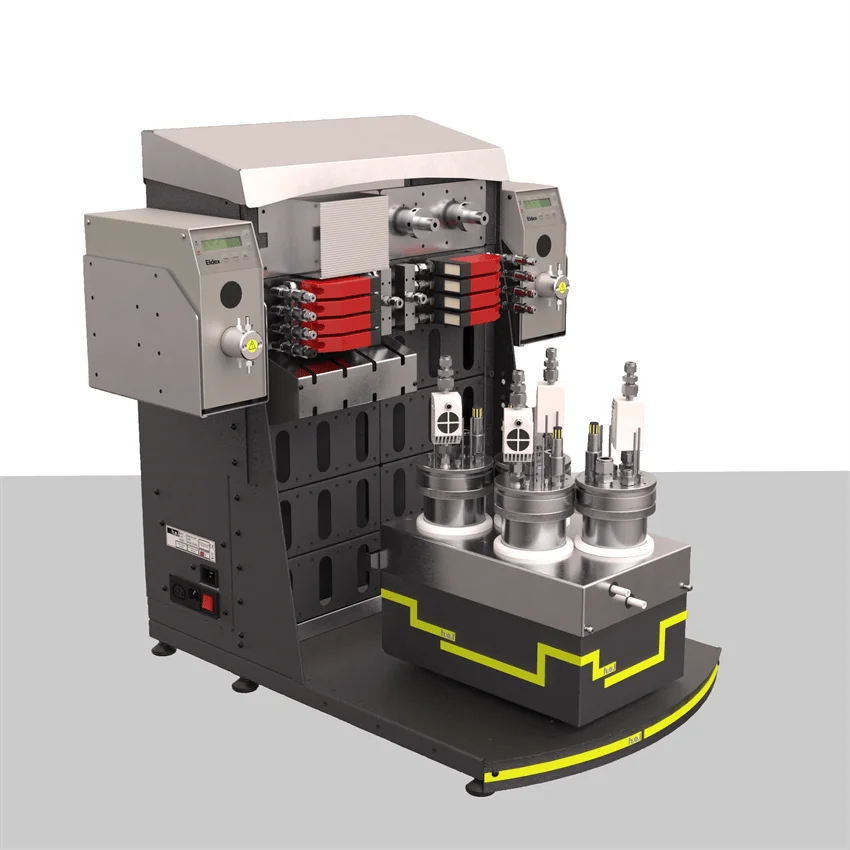

The BioXplorer 400P is an automated parallel pressure bioreactor system for the discovery and optimization of novel bioprocesses. Designed for applications ranging from syngas fermentation to cell-free enzymatically catalyzed processes, the BioXplorer 400P uses pressure and precision gas control to accelerate bioprocesses, which depend on the availability of dissolved gases.

The customizable configuration combined with versatile software allows the BioXplorer 400P to fulfill your precise needs, giving you the data you need to scale up faster.

Overview

Pressurized Bioprocessing

The BioXplorer 400P’s ability to run up to four parallel bioprocesses at up to 10 bar pressure is unique. More and more bioprocess scientists are turning to pressurized systems to increase the availability of dissolved gases and accelerate gas-dependent bioprocesses. The BioXplorer 400P is an indispensable tool for the optimization and scale-up of such processes. The system has been engineered with a focus on safety and ease of use. For example, the use of 2 gas spargers per reactor enables risks associated with potentially hazardous gas mixtures to be minimized. Adding pressure to accelerate your bioprocesses can deliver higher yields without compromising functionality and configurability.

Configurable System

The BioXplorer 400P uses a modular design and can be supplied with a wide range of probes, gas feeds, and liquid feeds, enabling it to be tailored to your precise needs. This maximizes functionality and ease of use while minimizing bench space requirements and cost.

Flexibility to optimize processes

The choice of probes to track the wide range of physicochemical parameters in bioprocess provides in-depth knowledge. Using H.E.L’s WinISO tight control and responsiveness, automatization of the process is possible. BioXplorer 400P can operate 4 bioreactors in parallel or independently, reducing the optimization time of bioprocecess

Features and Options

| Specification Point | BioXplorer 400P |

|---|---|

| Number of independent parallel bioreactors | 4 |

| Bioreactor material | Glass body, stainless steel lid |

| Total volume | 500ml |

| Working volume | 120 – 400 ml |

| Pressure rating | Up to 10 bar |

| Sterilization | Autoclavable bioreactors (including sensors) |

| Temperature Range | 0 – 135°C |

| Temperature resolution | 0.1°C |

| Stirrer drive | Magnetically driven captive impeller or Overhead agitation (magnetically coupled) |

| Stirrer speed |

|

| Auto re-couple |

|

| Liquid additions with independent control for each bioreactor |

|

| Gas additions | 1 set of 4 mass flow controllers allowing independent control for each reactor as standard, option for 2 additional sets |

| Standard options for MFC calibration | Air, oxygen, nitrogen, hydrogen, carbon monoxide, carbon dioxide or methane |

| Gas spargers | 2 |

| Exhaust gas | Peltier cooled condenser |

| pH control | 1-way control (2-way control optional) |

| Polarographic DO sensing | Optional |

| DO control | Gas/liquid flow rate, stirrer speed (Optional) |

| BioVIS – Understand cell density trends without taking samples | Optional |

| Foam/Level detection | Optional |

| Control PC and software | Windows® PC with WinISO control software preinstalled:

|

* Upper temperature limit for data acquisition from standard pH probes and optional ORP probes is 130°C. The optional DO probe measures at temperatures above 135°C. The lower temperature limit requires an integrated circulator option.