BTSorb

- Performs breakthrough curve testing and multi-component competitive adsorption.

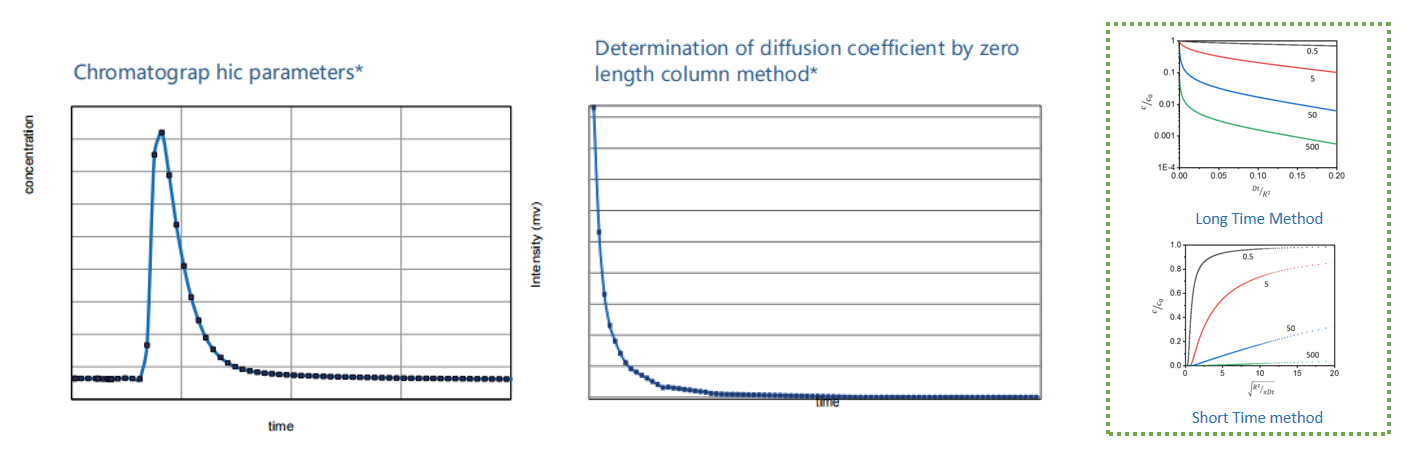

- Optional analysis of mass transfer performance, including diffusion coefficients via chromatography and ZLC methods.

- Supports PSA, TSA, and liquid-phase sorption experiments.

- Stable, constant-temperature system for reproducible results.

- Operates up to 100 bar for high-pressure gas separations.

- Optional configurations include vapor handling, integrated mass spectrometry, and sulfur-resistant corrosion protection.

Product Category: Gas Adsorption/Physisorption, Pore Size Determination and Distribution

Industry: Batteries, Mining and materials, Particle and surface science

Supplier: AMI

Description

- The BTsorb 100 series is a new line of cost-effective material characterization instruments designed for breakthrough curve testing, competitive adsorption, and mass transfer kinetics analysis. It is a comprehensive, versatile, and precise dynamic sorption analyzer.

- • Accurate: Trusted results you can rely on.

• Accessible: Cost-effective without compromise.

• Advanced: Engineered for high-performance.

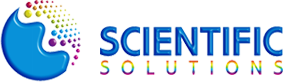

FEATURE

CAPABILITIES

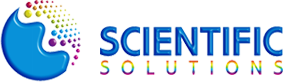

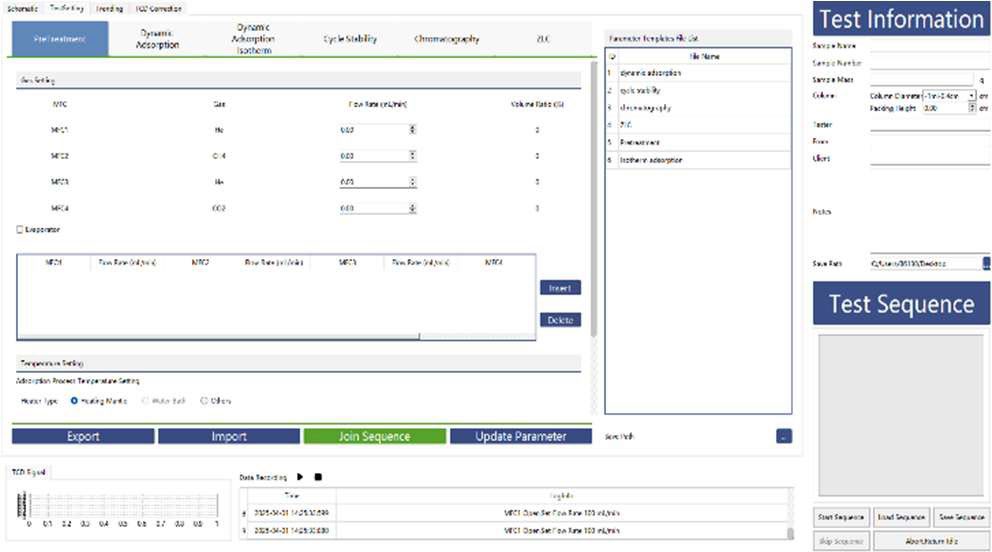

- The BTsorb 100 offers 5 modes for breakthrough curve and competitive adsorption analysis, enabling dynamic evaluation of gas or gas/vapor mixture separation. It also includes 2 dedicated modes for diffusion studies using chromatography and the zero-length column method.

- 5 Modes for Breakthrough Curve & Competitive Adsorption:

- 2 Modes for Diffusion Coefficients:

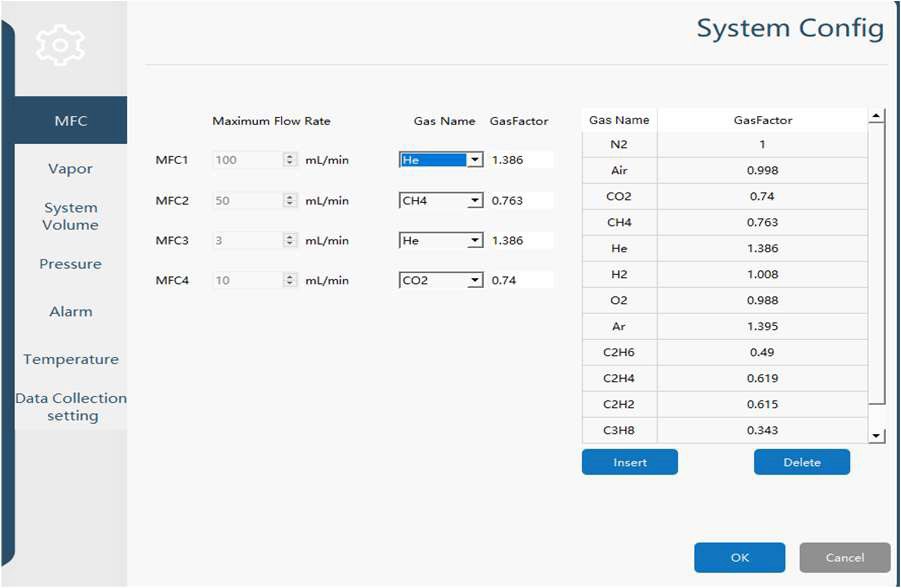

SOFTWARE

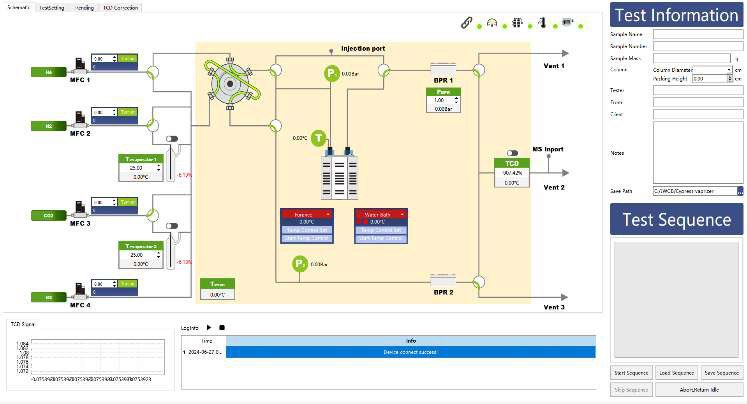

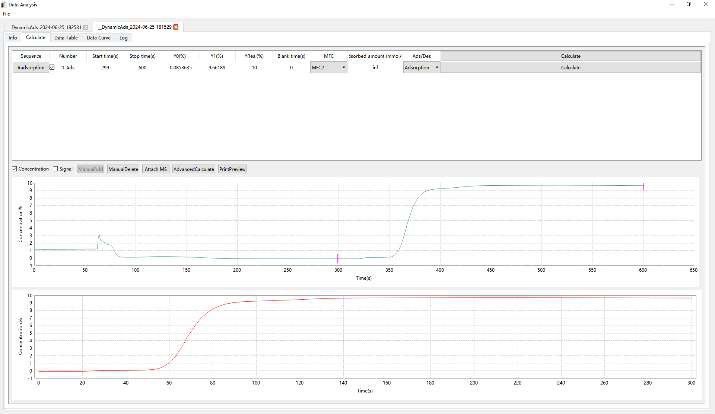

- BTManager is a user-friendly software platform that enables precise control of all experimental processes, while automatically recording data and calculating test results. It offers a range of features designed to simplify and support user operation.

- √ In addition to standard procedures, the software allows full customization of experimental steps to meet specific testing requirements.

√ All experimental steps and data are automatically recorded, making it easy for users to review and analyze results.

√ As part of a fully automated system, BTManager enables conditional controls based on time, temperature, pressure, and detector signals—ensuring precise execution, repeatability, and accuracy.

√ Includes advanced features such as blank adsorption correction, true flow calibration, abnormal data detection, and TCD signal calibration—minimizing environmental and system influences for highly reliable results.

- Control interface

- Data analysis interface

- Experimental parameter setting interface

- System configuration interface

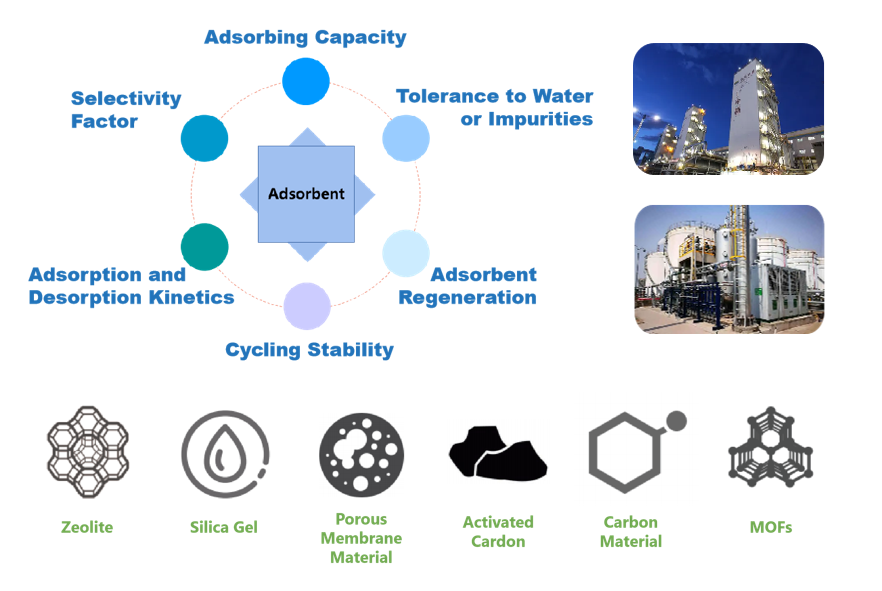

APPLICATION

- The BTsorb 100 series is primarily used to evaluate the adsorption and separation properties of porous materials. Common samples include MOFs, zeolites, silica gels, activated carbons, and other functional adsorbents. These materials are widely applied in processes such as gas separation purification, and CO2 capture, The BTsorb 100 meets the broad range of dynamic sorption analysis needs for these applications.

Specifications

SPECIFICATIONS

-

BTSorb 100 Series Breakthrough Curve and Mass Transfer Analyzer Breakthrough Curve Analyzer Model 100S Pro 100SLP Pro 100SMP Pro 100S 100SLP 100SMP 100SHP Breakthrough Curve √ √ √ √ √ √ √ Competitive Adsorption √ √ √ √ √ √ √ Adsorption Isotherm √ √ √ √ √ √ √ Cyclic Stability V V V V V V V Temperature Swing Adsorption √ √ √ √ √ √ √ Pressure Swing Adsorption / √ √ / √ √ √ Diffusion Coefficient √ √ √ / / / / Pressure Range Atmospheric Atm -10 bar Atm -40 bar Atmospheric Atm -10 bar Atm -40 bar Atm -100 bar MFCs 4 MFCs (1 carrier + 3 adsorbate) Gas Inlets Standard 4 ports(expandable with MGC-option) Vapor Dosing Up to 2 vapor generators(temperature control -10°C to 90°C) Temperature Control Standard:

Heating module: Ambient - 400 °C; Circulating water bath: -10 - 90°C; Option: Heating furnace: Ambient -1000°C; (Continuous temperature control from -10°C to 400°C can be achieved through the combined use of heating module and circulating water bath)Standard:

Heating module: Ambient - 400 °C; Option: Circulating water bath: -10 - 90°C; Heating furnace: Ambient - 1000°C; (Continuous temperature control from -10°C to 400°C can be achieved through the combined use of heating module and circulating water bath)Detector Standard: High precision Thermal Conductivity Detector (TCD)

Option: Mass spectrometer (100amu - 200/300 amu optional)Column Standard: 1 ml and 4 ml 316SS

Option:1ml and 4ml quartz; column for ZLCCorrosion Resistance Standard: Corrosion-resistant TCD

Option: Sulfur-resistant corrosion protection gas path upgrade,

passivation treatment of fittings and tubing is mainly used for sulfur - containing gases (such as H₂S) and scenarios with high - concentration of corrosive gases.Air Compressor Used to drive pneumatic valves (option)