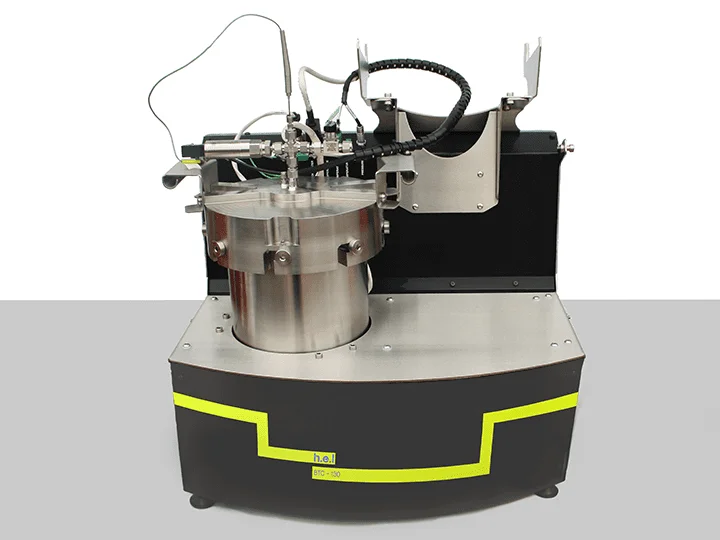

BTC-130 | Bench-Top, Battery Safety Testing, Adiabatic Calorimeter

- Component hazard Screening

- Characterizing differences in cell performance

- Defining safe operating limits

- Exploring thermal runaways and thermal propagation

Product Category: Battery Testing, Calorimeter

Industry: Batteries

Supplier: H.E.L. Group

Description

Applications

Safety Testing

Component hazard screening:

- Batteries are used in a wide variety of environmental conditions and undergo internal heating and cooling from both normal use and stress conditions. Therefore, it is vital to understand how individual cell components will behave under a range of temperatures early on in development. If a new cell component has a low temperature of self-heating, it could pose a thermal runaway risk. Similarly, if a rapid increase in pressure accompanies a thermal event, or if toxic gases are produced, this may indicate the use of the component should be reassessed. The BTC-130 facilitates the use of small volume test cells in addition to supporting the testing of small battery cells. This enables the thermal stability of individual cell components to be assessed under adiabatic conditions and informed decisions on how to proceed with cell development to be made.

Define safe operating limits:

- It is essential to identify the safe operating limits of battery cells, modules, and packs in order to avert the risk of thermal runaway, and the potentially catastrophic consequences to which it could lead. Therefore, batteries need to be subjected to mechanical, electrical, and thermal stresses in order to define their safe operating limits.

- Thermal stability data from thermal stress tests can help define the safe working temperature of the battery

- The evaluation of over-charging and discharging rates allows the maximum safe voltage and maximum safe current to be determined

- The consequences of mechanical stresses and external short circuits (ESC) can be evaluated

Exploring thermal runaways and thermal propagation

- In general, most extreme conditions can result in thermal stress on the battery cell, which can lead to a thermal runaway. Therefore, for the development of safe batteries, it is essential to understand the mechanism of the thermal runaway in a cell, and how it propagates within a module or pack so that appropriate mitigation strategies can be implemented.

The data obtained from the stress tests performed in the BTC-130 and the BTC-500 can be used to model a cell’s predicted thermal behavior. Successive onset temperatures of decomposition of components within the cell can be detected, and the resultant heat released determined. This can help to facilitate a mechanistic understanding of the thermal runaway within the cell. Further insight can also be derived from the external analysis of the composition of any evolved gases collected.

Performance Testing

Characterize differences in cell performance

- The BTC-130 and BTC-500 can be used to characterize the cell performance under more extreme operating conditions. The absolute limit of safe, repeated use can be assessed with the automated cycling of the battery cell until the heat generated by its discharge causes the onset of self-heating. Similarly, puncture tests provide an indication of the structural stability of the cell.

Features and Options

Type of Test

- Thermal stress: the BTC-130 enables the battery cell to be tested for its thermal stability and for the characterization of associated thermal runaway events.

- Electrical stress: the BTC-130 can be combined with charge-discharge units to support overcharging and discharging testing. External short circuits can also be applied. Resultant thermal runaway events can be characterized

- Mechanical stress: the BTC-130 can perform nail penetration puncture tests, while also characterizing the subsequent thermal runaway.

- High data rate acquisition, up to 10,000 Hz is available for characterizing extremely fast reactions. 100 Hz data acquisition and unique tests are available for compliance with GB/T 36276-2018

Battery/Sample Size

- Cell components, coin cells, small pouch cells, and cylindrical cells.

- Optional spherical test cells (pressure range 1-150 bar) for cell component testing.

Temperature Control

- Ambient to 500 °C.

Intelligent Software Control and Analysis

- Control software enables regular data logging, multi-step recipes, parameter control, and feedback loops.

Safety Features

- Automatic, user-configurable event detection and shutdown procedures, to ensure user safety

- Automatic hardware and software fail-safes are installed on every system

Whitepapers

Publications

The following are a list of some technical publications which highlight the use of the equipment.

Revealing the failure mechanisms of lithium-ion batteries during dynamic overcharge

Guangxu Zhang, Xuezhe Wei, Jiangong Zhu, Siqi Chen, Guangshuai Han and Haifeng Dai

30-Sep-2022

https://www.sciencedirect.com/science/article/abs/pii/S0378775322008552(Subscription or purchase maybe required for full access)

Robust Self-Standing Single-Ion Polymer Electrolytes Enabling High-Safety Magnesium Batteries at Elevated Temperature

Xuesong Ge, Fuchen Song, Aobing Du, Yaojian Zhang, Bin Xie, Lang Huang, Jingwen Zhao, Shanmu Dong, Xinhong Zhou and Guanglei Cui

29-Jun-2022

https://onlinelibrary.wiley.com/doi/abs/10.1002/aenm.202201464(Subscription or purchase maybe required for full access)

High performance polyimide-based separator for 4.5V high voltage LiCoO2 battery with superior safety

Kecong Yang, Zelin Liu, Jingchao Chai, Yun Zheng, Xiangnan Fu, Yang huan Shen, Jia Chen, Zhihong Liu and Shengwei Shi

15-Apr-2022

https://www.sciencedirect.com/science/article/abs/pii/S0254058422002814(Subscription or purchase maybe required for full access)

Revealing the multilevel thermal safety of lithium batteries

Gaojie Xu, Lang Huang, Chenglong Lu, Xinhong Zhou, Guanglei Cui

01-Oct-2020

https://doi.org/10.1016/j.ensm.2020.06.004(Subscription or purchase maybe required for full access)

Effects of Overdischarge Rate on Thermal Runaway of NCM811 Li-Ion Batteries

Dong Wang, Lili Zheng, Xichao Li, Guangchao Du, Zhichao Zhang, Yan Feng, Longzhou Jia and Zuoqiang Dai

30-Jul-2020

https://doi.org/10.3390/en13153885(Subscription or purchase maybe required for full access)

Reduced shuttle effect by dual synergism of lithium–sulfur batteries with polydopamine-modified polyimide separators

Yanqing Wang, Zengqi Zhang, Lintao Dong, Yongcheng Jin

01-Feb-2020

https://doi.org/10.1016/j.memsci.2019.117581(Subscription or purchase maybe required for full access)

Deciphering the Interface of a High Voltage (5 V-Class) Li-Ion Battery Containing Additive-Assisted Sulfolane-Based Electrolyte

Di Lu,Gaojie Xu,Zhiwei Hu,Zili Cui,Xiao Wang,Jiedong Li,Lang Huang,Xiaofan Du,Yantao Wang,Jun Ma

06-Sep-2019

https://doi.org/10.1002/smtd.201900546(Subscription or purchase maybe required for full access)

Testimonials

BTC-130

We at TUV Rheinland consider ourselves to be quite fortunate in finding a vendor like HEL as the supplier of our Adiabatic Battery Testing Calorimeter. Not only does HEL provide a dynamic, but also a flexible team to work with. HEL’s expertise and experience in calorimetry has proven to be one of their strongest assets. The joint partnership with HEL has enabled us to develop services from which our company and our customers have benefited. We feel this BTC system has been a key factor to the success of our laboratory.

Japan - TUV Rheinland Battery Laboratory